Sintering and Oxidation of GdB4 Synthesized by B4C Reduction Method

Article information

Abstract

Gadolinium tetraboride (GdB4) was synthesized by reduction of Gd2O3 using boron carbide in presence of carbon. Effect of temperature on product quality was investigated. Pure GdB4 powder was obtained in vacuum at 1500°C. Pressureless sintering experiments revealed that sintering takes place only above 1600°C. A maximum density of 77.1% of the theoretical value was obtained at 1800°C by pressureless sintering. Hot pressing resulted in 95.5% of theoretical density at the lower temperature of 1700°C under 35 MPa pressure. Hardness and fracture toughness of dense GdB4 were measured and found to be 21.4 GPa and 2.3 MPa·m1/2, respectively. After exposure to air at 900°C, the formation of a porous and non-protective oxide layer was observed.

1. Introduction

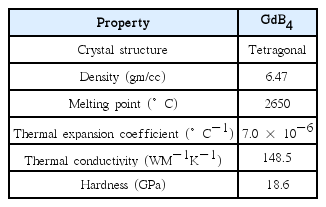

Rare earth borides are exceptional ceramics characterized by high melting point, high hardness, excellent thermal stability, low vapour pressure, high electrical and thermal conductivity and low thermal expansion coefficient.1) Due to high neutron absorption cross section of boron, rare earth borides are candidate materials for neutron absorber applications in nuclear reactors.2–4) They are good thermionic electron emitters due to their low work function, low vapour pressure, high brightness and long service life.5–7) Though borides of Lanthanum (La) and Cerium (Ce) have been studied extensively, literature on Gadolinium boride has been minimal. The high neutron absorbing capacity of Gd and boron makes the resulting compound suitable for neutron absorber applications in nuclear reactors. In the Gd-B system, the GdB4 phase is the most stable. Important properties of GdB4 are listed in Table 1.

Most of the literature on GdB4 has been concerned with its physical properties.8–10) Reports on synthesis and densification of GdB4 have been very limited.5,11,12) Lazorenko et al.11) prepared GdB4 by borothermic reduction of Gd2O3 at around 2000°C in vacuum. Itoh et al.12) prepared GdB4 and GdB6 by decomposition of the boron cage compound Gd2(B10H10)3.

Gadolinium tetraboride powder is not easily available. In the present study, a process has been developed to prepare GdB4 powder. In this process, GdB4 was synthesized by boron carbide reduction of Gd2O3 in the presence of carbon, as per Eq. (1). We have not come across any report on the synthesis of GdB4 powder by boron carbide reduction method. This method is expected to be economical since the raw materials are Gd2O3, B4C and carbon, which are comparatively less expensive than elemental Boron and boron cage compounds used in previous studies.11,12)

In many applications, borides are required to be in the form of dense shapes. Sintering of borides is a challenging task because the high melting point and low self diffusivity of these materials make sintering difficult.13–15) Moreover, boride powders are generally covered with surface oxide layers that decrease the surface energy of the particles.13–15) In this study, pressureless sintering and hot pressing techniques were investigated for obtaining GdB4 in the form of dense pellets.

Many borides are susceptible to oxidation, which limits their application in high temperature oxidizing environments. In this study, an oxidation test of GdB4 was carried out to explore the possibility of using this material in high temperature oxidizing environments.

This study reports on the results of investigations of the synthesis, consolidation and oxidation behaviour of GdB4. To the best of authors’ knowledge, there is no published report on densification and oxidation of GdB4.

2. Experimental Procedure

2.1. Starting material

Gd2O3 (99.9% purity, supplied by M/s Advanced Technology Materials, Mumbai), B4C (78.5% B, 19.5% C, < 1% O, 0.02% Fe, 0.02% Si; 5.34 μm particle median diameter; supplied by M/s Boron Carbide India) and petroleum coke (99.4% purity; 13.9 μm median particle diameter, supplied by M/s Assam Carbon, India) were used as starting materials. The starting materials were characterized by X-ray diffraction (XRD) analysis using Cu Kα (λ = 1.5404 Å) radiation; this method has a detection limit of 4 vol%. Fig. 1 presents the XRD patterns of the starting powders, and confirms that there is no impurity phase in the starting powders, within the detection limit of XRD.

2.2. Synthesis

For the synthesis of GdB4, weighed quantities of gadolinium oxide, boron carbide and carbon in stoichiometric ratios were mixed thoroughly in a motorized mortar and pestle. The powder mixture was then pelletized under a pressure of about 200 MPa to obtain green pellets of 12 mm diameter. The pellets were then placed in a graphite crucible and heated in an induction furnace at a fixed temperature between 1200 to 1500°C for dwelling period of 2 h under a dynamic vacuum of 2 × 10−5 mbar. The temperature of the charge was measured using a two-colour pyrometer with an accuracy of ± 20°C. After the dwelling period, the furnace was allowed to cool to room temperature under vacuum; then, the partially sintered pellets were taken out, crushed and ground to a fine size using a high energy tungsten carbide lined cup grinding mill.

Major phases of powders were identified by XRD using Cu Kα (λ = 1.5404 Å) radiation. Carbon and oxygen were measured by combustion method and by inert gas fusion (IGF) method, respectively. Particle morphology was examined by scanning electron microscope (SEM).

2.3. Densification

In the pressureless sintering (PS) experiments, GdB4 powder was cold compacted under a pressure of about 280 MPa to form pellets of 12 mm diameter and 5 mm height with a green density of ~ 62% of the theoretical density (ρth). These compacts were sintered at a temperature between 1200 to 1800°C under a dynamic vacuum of 2 × 10−5 mbar in an induction furnace for holding periods of 2 h. In the hot pressing experiments, fine powders were hot pressed under a vacuum of 2 × 10−5 mbar in a high density graphite die (17 mm hole) by applying 35 MPa pressure at 1700°C for 2 h. The densities of the pellets were measured by the Archimedes principle. The fracture surfaces of the dense pellets was examined by SEM. The samples were broken by hammering to obtain a fracture surface.

Densified samples were polished to a mirror finish using diamond powder of various grades from 15 to 0.25 μm in an auto polisher (laboforce-3, Struers). Microhardness was measured at a load of 100 g and dwell time of 10 sec. Indentation fracture toughness (KIc) data were evaluated by crack length measurement of the crack pattern formed around the Vickers indents (using 10 kg load), adopting the model formulation proposed by Anstis et al.16) KIC = 0.016(E/H)1/2P/c3/2, where E is the Young’s modulus, H the Vickers’s hardness, P the applied indentation load, and c the half crack length.

2.4. Oxidation

Isothermal oxidation study of the dense GdB4 was carried out at a temperature of 900°C for different time intervals. A hot pressed pellet of diameter 17 mm was cut into thin slices of 3 mm thickness. All the surfaces of the cut sample were ground with emery papers (1/0, 2/0, 3/0, 4/0) and finally polished with diamond paste to achieve a 1 μm finish. Oxidation tests were conducted in a resistance heated furnace. In order to avoid oxidation during heating, the sample was directly inserted into the hot zone after the furnace had reached the set temperature. Sample was placed in an alumina crucible loaded inside the furnace. The sample was oxidized in air for different time intervals (4, 8, 16, 32) at the set temperature of 900°C. The sample was carefully weighed to an accuracy of 0.01 mg before and after exposure, to determine the weight change during the oxidation process. The morphology and nature of the oxide layer were established by observing the surface in a field emission scanning electron microscope (FE-SEM) with energy dispersive spectroscopy (EDS). The phases present on the oxidized surface were analysed by XRD.

3. Results and Discussion

3.1. Synthesis

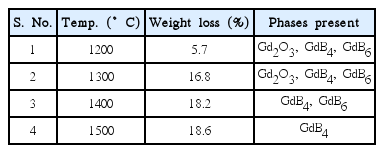

Table 2 presents the processing parameters and results of synthesis experiments carried out in a vacuum induction furnace. At 1200 and 1300°C, weight loss noticed is about 5.7% and 16.8%, respectively, which values are lower than the theoretical weigh loss (17.3%), indicating that the reaction had started but did not complete. The product was analysed and found to contain Gd2O3, GdB4 and GdB6 phases. The presence of Gd2O3 confirms the incomplete reduction. Sample processed at 1400°C was observed to contain GdB4 and GdB6 phases. Only at a temperature of 1500°C was single phase GdB4 obtained. The carbon and oxygen content of GdB4 were measured and found to be 0.5 wt.% each.

Figure 2 presents the XRD patterns of the samples processed at different temperature. The XRD patterns reveal that the product obtained at 1500°C is pure GdB4, whereas products obtained at lower temperatures also contain the Gd2O3 and GdB6 phase. The GdB6 phase could have formed via the following side reaction (reaction (2)).

At higher temperatures, the reaction kinetics for reaction (1) was fast and all the Gd2O3 was converted to GdB4. In the Gd-B system, GdB4 is the most stable phase. Free energy calculations for reactions (1) and (2) could not be done as thermodynamic data for GdB4 and GdB6 are not available.

Though the reaction starts at a lower temperature (< 1200°C), pure GdB4 is obtained only at 1500°C. At low temperature, the reaction kinetics is very slow and hence a high temperature is required for faster diffusion of the solid reactant atoms through the product that formed at the interface.

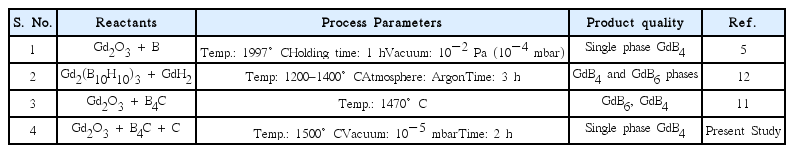

The scientific literature on the processing of GdB4 is scant, which was the motivation for this work. A summary of past studies is provided in Table 3.5,11,12) The borothermic reduction process involves the use of elemental boron, which is expensive and pyrophoric. Preparation of GdB4 by boron cage compounds and metal hydrides requires one additional step, as these materials are not readily available. Handling of metal hydride is also difficult due to its pyrophoric nature. Preparation by reaction between Gd2O3, B4C and carbon seems to be the best process as it involves readily available charge material and does not have any handling issues. The process is also suitable for large scale production of boride powder. In this study, single phase GdB4 was obtained.

Synthesis of other rare earth borides by this route has been reported in literature. Zaykoski et al. have prepared aYB4 ceramic by this route at 1800°C in helium atmosphere.17) Liu et al.18) have reported that NdB6 powder can be prepared by boron carbide reduction of Nd2O3 at 1500°C in vacuum. Xu et al.19) have prepared LaB6 by this route at 1650°C at atmospheric pressure. Sonber et al. have prepared LaB6, EuB6 and CeB6 by this route.13,20,21)

3.2. Densification and characterization

The particle size distribution of synthesized GdB4 powder that was ground using a high energy vibratory cup mill is presented in Fig. 3, which shows a bimodal distribution of particles with peaks at 2.5 mm and 10 mm. Mean particle diameter was found to be 5.6 mm. An SEM image (Fig. 4) of the powder shows particle agglomerates of 4 – 7 mm size.

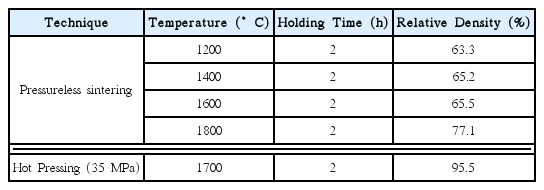

Results of pressureless sintering and hot pressing experiments are summarized in Table 4. Results of pressure less sintering at temperatures upto 1600°C have shown that the obtained density is close to the green density of 63%, and that no densification took place during sintering. At 1800°C, densification started and a density of 77.1% of the theoretical value was obtained. The presence of high porosity (~ 23%) after sintering at 1800°C indicated that the densification of GdB4 by pressureless sintering is extremely difficult. Hot pressing of GdB4 at 1700°C under 35 MPa pressure resulted in a density that was 95.5% of the theoretical density.

The poor sinterability observed in monolithic GdB4 is due to this material’s high refractoriness and low intrinsic self diffusivity, which are also observed in other borides.13,14) Arabei et al.15) have reported that the densification processes of hexaborides becomes activated at temperatures in the range of 1800 – 2000°C. Zaykoski et al.17) have prepared fully dense YB4 by hot pressing at 1800°C.

Figure 5 provides an SEM image of the fracture surfaces of the pressureless sintered samples. Porosity is present in all the samples. The image also shows that there is no grain growth in the sample processed at 1200 and 1400°C. Grain growth was observed in the sample processed at 1800°C. Fig. 6 shows the fractured surface of the hot pressed GdB4; this surface shows a dense microstructure.

SEM images showing fracture surfaces of GDB4 prepared by pressureless sintering at (a) 1200°C (b) 1400°C and (c) 1800°C.

3.3. Property characterization of hot pressed GdB4

3.3.1. Mechanical Properties

The hardness of the dense GdB4 sample (95.5% dense) was measured and found to be 21.4 GPa. In the literature, the hardness of GdB4 was found to be 18.6 GPa.1) The fracture toughness of the dense GdB4 sample (95.5% dense) was found to be 2.3 MPa·m1/2. In the literature, there are no data available on fracture toughness measurement of GdB4.

3.3.2. Oxidation study

Figure 7 presents the specific weight gain vs. time plot during isothermal oxidation of GdB4 in air at 900°C. The plot shows linear behavior of the weight gain with time, which is a signature of a non-protective oxide layer. Specific weight gain values of 3.27 mg/cm2 and 52.66 mg/cm2 were measured after 4 h and 32 h, respectively.

Specific weight gain with time in GdB4 sample during oxidation at 900°C (line joining points are forvisual aid only).

Figure 8 provides an SEM image of the oxidized surface after oxidation. This image shows the presence of a porous and non-protective oxide layer on the surface. Fig. 9 shows the typical EDS pattern of the oxide layer. This indicates the presence of gadolinium, oxygen and boron on the oxidized surface. Fig. 10 shows the XRD pattern of the oxidized surface, which indicates the presence of GdBO3 only as a crystalline phase. GdBO3 could have been formed by reaction (3) during oxidation.

Free energy of formation for reaction (3) could not be calculated because thermodynamic data for GdB4 are not available.

There has been no report on the oxidation behaviour of GdB4. In one study,17) pure YB4 was found to show considerable oxidation above 1200°C, and also resulted in the formation of a borate phase (YBO3), similar to the oxidation behaviour of GdB4 shown in the present study.

4. Conclusions

Conclusions that can be obtained from the present study are summarized as follows.

GdB4 powder was synthesized by boron carbide reduction of Gd2O3 at 1500°C in vacuum.

Pressureless sintering study of monolithic GdB4 revealed that there is no densification until 1600°C.

It was possible to achieve a maximum density of 77.1% of the theoretical density at 1800°C.

Full densification was achieved by using hot pressing of GdB4 powder at 1700°C.

Hardness and fracture toughness of fully dense GdB4 was measured and found to be 21.4 GPa and 2.3 MPa·m1/2, respectively.

Oxidation study of monolithic GdB4 revealed the formation of a non-protective, porous oxidized layer consisting of GdBO3 after isothermal oxidation testing at 900°C in an air atmosphere.