1. Introduction

Lead-based ceramics, particularly La substituted lead zirconate titanate (PLZT), is widely used for various electric/electromechanical applications owing to its reliable, repeatable, and reasonably good electrical properties. The ratio of Pb/La at the A-site and Zr/Ti at the B-site in PLZT determines not only its crystal phase, microstructure, morphology, and electrical characteristics, but also determines whether the material exhibits, paraelectric (PE), ferroelectric (FE), anti-ferroelectric (AFE), and relaxor ferroelectric (RFE) behaviors. The PE, FE, AFE, and RFE nature of electro-ceramics are extensively investigated regarding their energy storage density properties and related applications. 1-6) Focus is given to those materials with a high stored energy density and energy efficiency because they can be used in various applications, from general (camera flashes, wind turbine generators, high-frequency inverters, and hybrid electric vehicles) and medical (pacemakers, defibrillators, and surgical lasers) to defense (radar and ballistic missiles) applications.7-9) Among PE, FE, and RFE, ceramics with an AFE nature have greater energy storage with moderate efficiency given their special double-type hysteresis. In this context, among the various AFE materials, PLZT ceramics are a good candidate for high energy density materials. Some compositions of PLZT AFE ceramics have been studied for their high stored energy density properties. One composition, (Pb0.93La0.07)(Zr0.82Ti0.18)O3 (PLZT 7/82/18) AFE ceramics, was investigated for its large electrocaloric effect (ECE).10) As is well known, materials with high entropy changes under an applied electric field show high ECE and pyroelectric properties. Materials with a high pyroelectric coefficient are used to scavenge and detect stray thermal energy for conversion into electrical energy, which can provide a cost-effective and reliable energy source for modern electrical appliances, sensor applications, flexible pyroelectric devices, and hybrid energy harvesting. Not only can PLZT 7/82/18 AFE ceramics demonstrate a large pyroelectric coefficient, they can also be used in high energy storage owing to a double hysteresis nature, as mentioned earlier.

For the synthesis of PLZT ceramics, the A-site (Pb2+) of the PZT ceramics is replaced by an off-valent donor (La3+). These off-valent modified materials are also known as soft electro-ceramics and show square P-E loops with a high hysteresis loss, which is undesirable in the case of energy storage applications. By contrast, hard ceramics (off-valent acceptors) are difficult to polarize or depolarize but are more stable than soft ceramics, although they exhibit poorly developed hysteresis loops, lower dielectric constants, low dielectric losses, and a low compliance, and cannot produce large displacements.11) The performance and properties of the electro-ceramics can be improved through doping using various oxide dopants such as CuO, ZnO, MnO, and MnO2.12-16) It is well known that when Mn is added to PZT-based ceramics without exceeding the solubility limit, the Mn ions are homogeneously dissolved in the perovskite structure, thereby enhancing the densification of the sample. More specifically, when the B-site ions in the perovskite structure (Zr4+, Ti4+) are substituted with Mn ions with lower valences (Mn2+ or Mn3+), to maintain the electrical neutrality, the following oxygen vacancies are created:17)

Mn-doping has been used not only for modulation of the dielectric, ferroelectric, and piezoelectric15,18-22) energy storage properties23) but also for improving the pyroelectric24) and multicaloric effects.25,26) Moreover, the effects of MnO2 content on the permeability and electrical resistance of porous alumina-based ceramics have also been reported.27) In this study, the dielectric and pyroelectric properties of PLZT 7/82/18 AFE ceramics were modulated and investigated systematically through Mn-doping. It was found that, with a small amount of Mn-doping, PLZT ceramics show high densification, dielectric, energy storage density, and efficiency characteristics compared to un-doped PLZT ceramics and their reported values.10)

2. Experimental Procedure

Stoichiometric quantities of commercially available reagent grade PbO, La2O3, ZrO2, TiO2, and MnO2 (≥ 99.9%, Sigma-Aldrich, USA) were used for the synthesis of (Pb0.93La0.07)-(Zr0.82Ti0.18)O3 AFE ceramics. Raw powders were ball milled in an ethanol medium for 24 h with zirconia balls. Calcination (phase) and sintering (density) procedures were conducted at 850°C and 1,250°C for 4 h, respectively. The heating rate for the calcination and sintering was kept at 5°C/min. To prevent the lead loss at high temperatures, bulk ceramic discs were muffled in the same powders. The detailed synthesis process can be found in a previous publication. 28) The X-ray diffraction pattern of sintered PLZT ceramics was recorded at room temperature using a PANa-lytical X’pert PRO X-ray diffractometer with monochromatic Cu Kα radiation (λ = 1.5406 Å). The microstructure of the PLZT ceramics was examined using a Hitachi S-4800 scanning electron microscope (SEM), and the grain size was calculated using Image-J software. Sintered PLZT ceramic discs were ground and polished using emery sheets, and the opposite faces of the pellets were coated with a silver paste to measure the electrical properties. A Keysight Impedance Analyzer E4990A was used for the dielectric measurements. The bipolar P-E measurements were traced using an aix-ACCT ferroelectric evaluation system. The pyroelectric properties were measured using a Poly K pyroelectric measurement system.

3. Results and Discussion

3.1. Structural and microstructural investigation

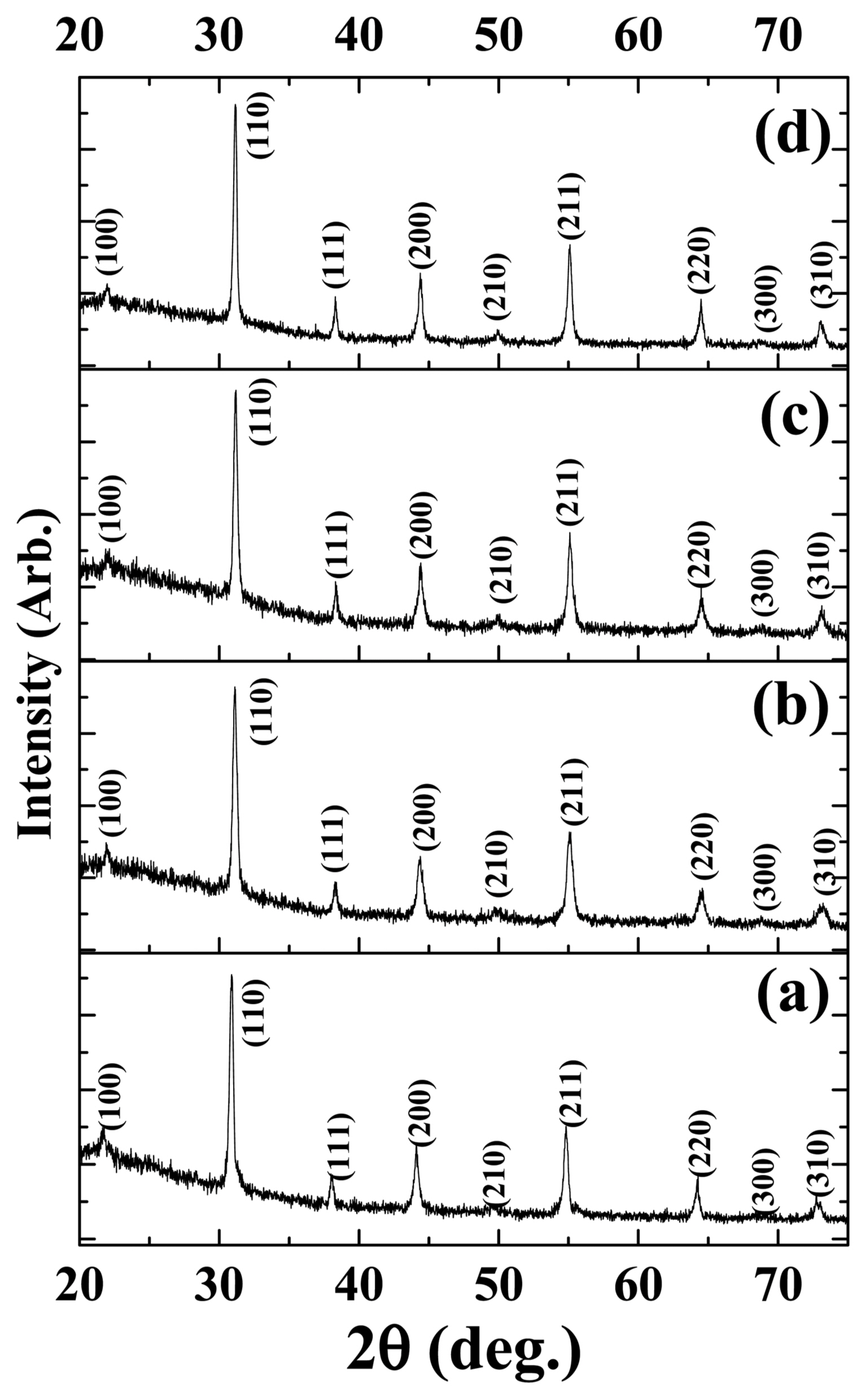

XRD patterns were obtained for sintered compacts of Mn-doped PLZT 7/82/18 AFE ceramics (Fig. 1). During the sintering process of Mn-doped PLZT ceramics, a chemical reaction between the raw oxides takes place and a pure perovskite PLZT phase is formed without any secondary phases, which indicates that Mn ions have diffused into the PLZT lattices and that a small amount of Mn-doping will not change the crystal structure of the PLZT AFE ceramics. The XRD results indicate that all Mn-doped PLZT AFE ceramics crystallize into a pure perovskite phase with a pseudocubic structure after sintering at 1,250°C. Because the ionic radius of Mn2+ (0.83 Å) and Mn3+ (0.645 Å) is much smaller than that of the A-site ions (Pb2+, 1.19 Å; La3+, 1.03 Å), Mn ions are more likely to substitute into B-site ions (Ti4+, 0.80 Å; Zr4+, 0.68 Å), which can cause the formation of oxygen vacancies such that the lattice may exhibit a small degree of shrinkage.23) Nevertheless, the lattice still increases due to the different ionic sizes, which can compensate for the shrinkage of the lattice. Therefore, no obvious changes to the XRD patterns or shift of the peaks of these ceramic samples were detected under different Mn-doping because of the similar ionic radius of Mn ions and B-site ions.15)

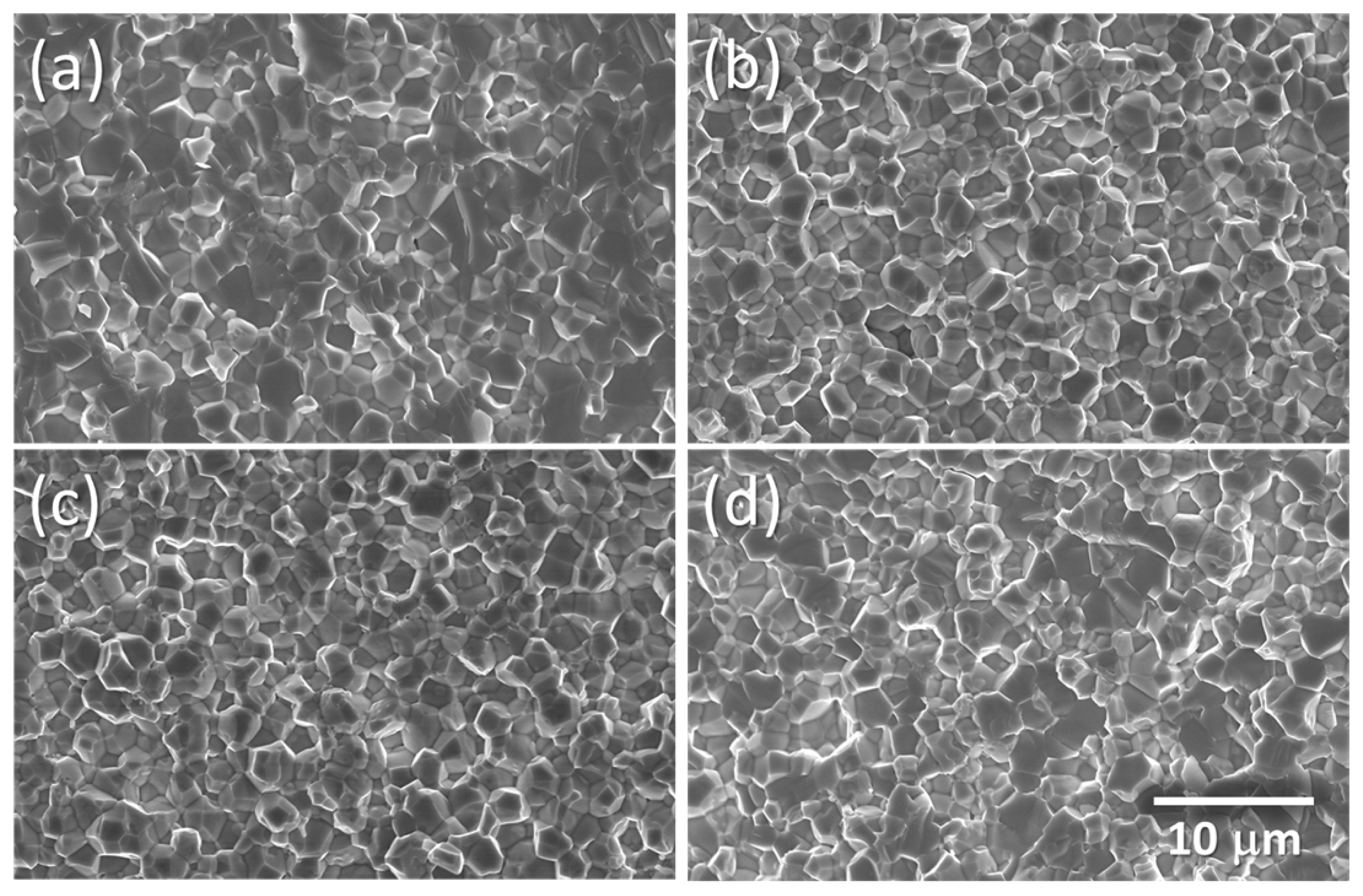

The grain size of the electro-ceramics is an important factor that can affect the tetragonality (c/a ratio), dielectric constant, phase transition temperature (Tc), polarization, domain wall switching, and piezoelectric and pyroelectric coefficients.29-33) SEM images of the fractured surface of Mn-doped PLZT 7/82/18 AFE ceramics were taken to calculate the grain size and analyze the grain shape, microstructure, and density (Fig. 2(a)-(d)). The average grain size for Mn-doped sintered PLZT ceramics changes as a function of the Mn-doping content. The average grain size for the 0.0%, 0.1%, 0.2%, and 0.5% Mn-doped PLZT ceramics was found to be 2.2, 2.5, 3.3, and 2.8 μm, respectively. The grain size first increases with Mn-doping, such that Mn = 0.2% doped PLZT ceramics have the largest grains, but then decreases. The slight increase in grain size with an increase in Mn content reflects the enhanced mobility of the constituent ions for grain growth. SEM images of the fractured surface of sintered PLZT 7/82/18 AFE ceramics indicates an extremely dense structure (low porosity) with uniform grain sizes with clear and visible grain boundaries, indicating the existence of a polycrystalline microstructure, which results in the good electrical properties exhibited. The density of the PLZT ceramics was measured using an Archimedes method with 0.0%, 0.1%, 0.2%, and 0.5% Mn-doping, and was found to be 7.42 g/cm3 (~ 93%), 7.67 g/cm3 (~ 96%), 7.70 g/cm3 (~ 96%), and 7.75 g/cm3 (~ 97%), respectively. With 0.1% Mn-doping, the density of the PLZT AFE ceramics increases slightly. PLZT ceramics were Mn-doped at up to 0.5% because, in another report, the PZT-PZT system shows a full density of up to 0.5 wt% of the MnO2 content; however, when the MnO2 content exceeded 0.5 wt%, the density decreased rapidly with a high porosity. A further increase in Mn-doping affected the sintering capability of PZT-PZN ceramics.17)

3.2. Dielectric properties

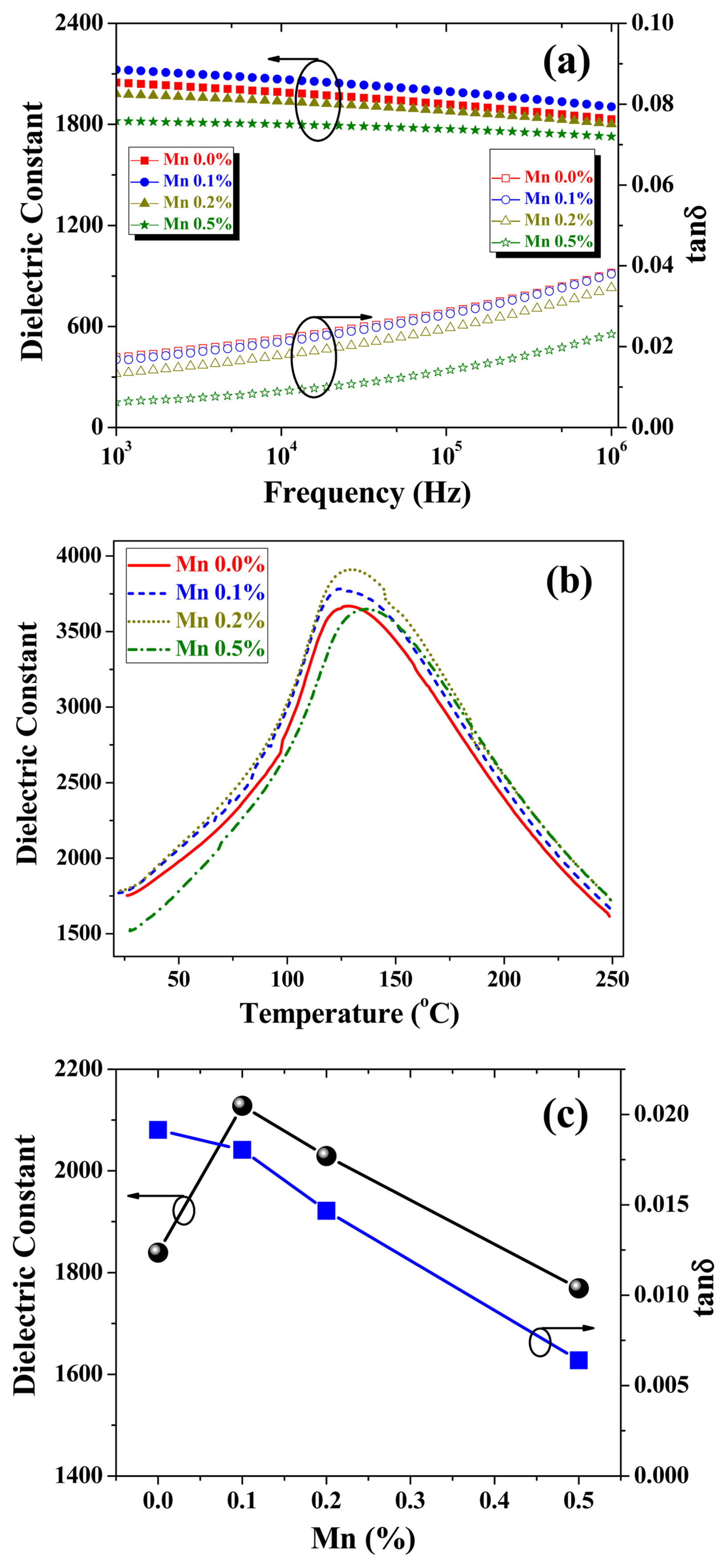

The frequency (1 kHz to 1 MHz) and temperature (30-250°C) dependent dielectric properties of Mn-doped PLZT 7/82/18 AFE ceramics are shown in Fig. 3(a) and (b), respectively. The dielectric constant and loss of the PLZT ceramic decreases as a function of Mn-doping. The room-temperature dielectric constant and loss values were found to be ~ 2,128 and ~ 0.018, respectively, as measured at 1 kHz, which correspond to the typical dielectric properties of AFE based on PLZT ceramics (0.1% Mn). Fig. 3(b) shows the dielectric constant versus temperature curves for the PLZT 7/82/18 AFE ceramics as a function of Mn-doing at a frequency of 1 kHz. As is well known, the PZT system shows a sharp phase transition at a comparatively high transition temperature (Tc = Tm).30,34) However, this sharp phase transition peak becomes broader and Tc becomes smaller when the A-site of the PZT ceramics is substituted with soft dopants such as La+3. The substitution of Pb+2 by La+3 can cause compositional fluctuations and substitutional disordering in the arrangement of cations in one or more crystallographic sites and microscopic or nanoscopic heterogeneity in the compounds. This results in a broad phase transition peak and reduced Tc with a diffuse-type phase transition. In this study, when PLZT ceramics are doped by Mn (0.0, 0.1, 0.2 and 0.5%), Tc shows an increase (127°C, 124°C, 130°C, and 136°C), and the peaks become broader. Fig. 3(c) shows an increase in the dielectric constant and a continuous decrease in dielectric loss value as a function of Mn-doing in PLZT AFE ceramics measured at 1 kHz. Owing to the B-site substitution of Mn ions, the formation of oxygen vacancies can increase not only the dielectric properties but also other electric properties. The decrease in the loss tangent indicates that the doping of MnO causes a “hard doping” effect in the PLZT AFE ceramics. The dielectric properties of the PLZT 7/82/18 AFE ceramics are given in Table 1.

3.3. Ferroelectric properties

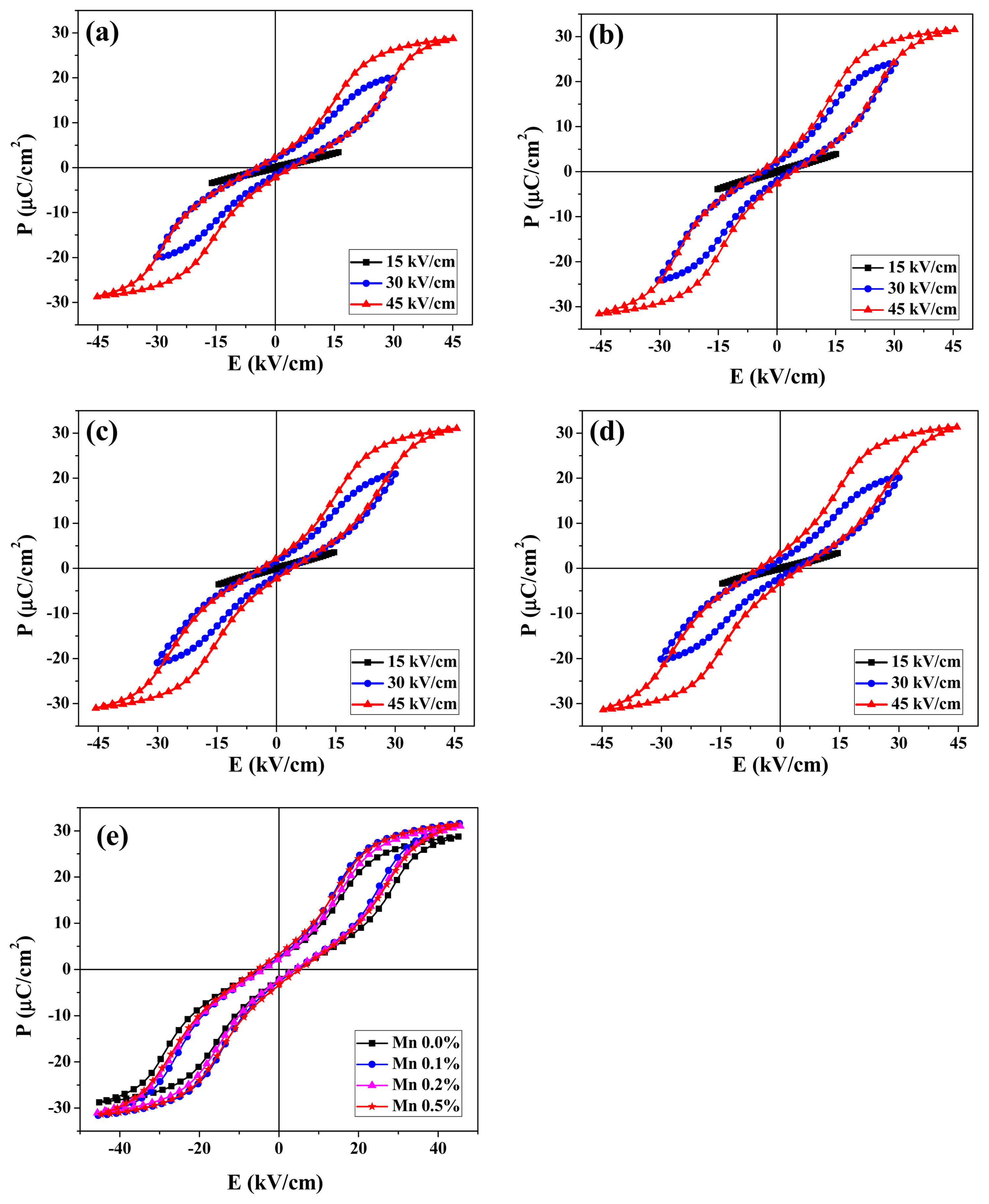

The P-E hysteresis loop is a fingerprint-like electrical characteristic of the materials and shows slim, square, and double hysteresis loops for the RFE, AFE, and FE ceramics, respectively. The shape of the P-E hysteresis loops is also affected by the measurement temperature (PE and FE), the doping in the original ceramic composition (A- and B-sites), and the microstructure of the ceramics (grain size and porosity).11,35,36) Moreover, P-E loops can also be used for an estimation of the energy density and efficiency of the ceramics. The values of Pr and Ec also help understand the microstructure of the ceramics. Fig. 4 shows the P-E hysteresis curves for Mn-doped PLZT 7/82/18 AFE ceramics, which are typical anti-ferroelectric-type double hysteresis loops. The shapes of the P-E loops with saturation polarization (Ps), remnant polarization (Pr), and a coercive field (Ec) are almost the same for Mn = 0.0%, 0.1%, 0.2%, and 0.5% doping; however, Mn = 0.2% shows a little improvement. The high value of Pmax (~ 31 μC/cm2) and low Pr (~ 2.2 μC/cm2) and Ec (~ 0.22 kV/cm) for Mn = 0.2% doping suggest that these materials are also suitable for energy storage applications. The sharp tip of the P-E loop suggests that PLZT ceramics have a high density, fine size, and uniform grains. Fig. 4(e) shows the P-E hysteresis loop for PLZT 7/82/18 AFE ceramics doped with Mn = 0.1%, 0.2%, and 0.5% measured at 45 kV/cm, which clearly shows that the higher percentage of Mn makes the PLZT ceramics comparatively harder and less saturated at a higher field.

Figure 5(a) shows the change in Pmax as a function of the electric field for Mn-doped PLZT AFE ceramics. It is clear that Pmax increases with Mn-doping and was found to be the highest for Mn = 0.2% doped PLZT AFE ceramics, which can be attributed to the improved microstructure of the PLZT AFE ceramics.37) Fig. 5(b) shows the maximum field (Emax) applied to the Mn-doped PLZT AFE ceramics. Here, Emax was found to have a decreasing trend with Mn-doping, which shows that Mn-doping can improve the electrical properties within a limited electric field range; however, excess doping and a high field result in an increase in leakage current, and finally, an electrical breakdown of the PLZT AFE ceramics. In hard doping, with acceptor dopants (Mn2+) added into ceramics, oxygen vacancies are created, which are well known for the pinning effect with respect to domain wall motion. Pinning of the domain walls can increase the mechanical quality factor and reduce the dielectric loss. Moreover, this domain wall motion pinning can result in less saturation of the PLZT ceramics because fewer domains are now available for the free movement, resulting in a reduced breakdown field and low domain switching current.19)

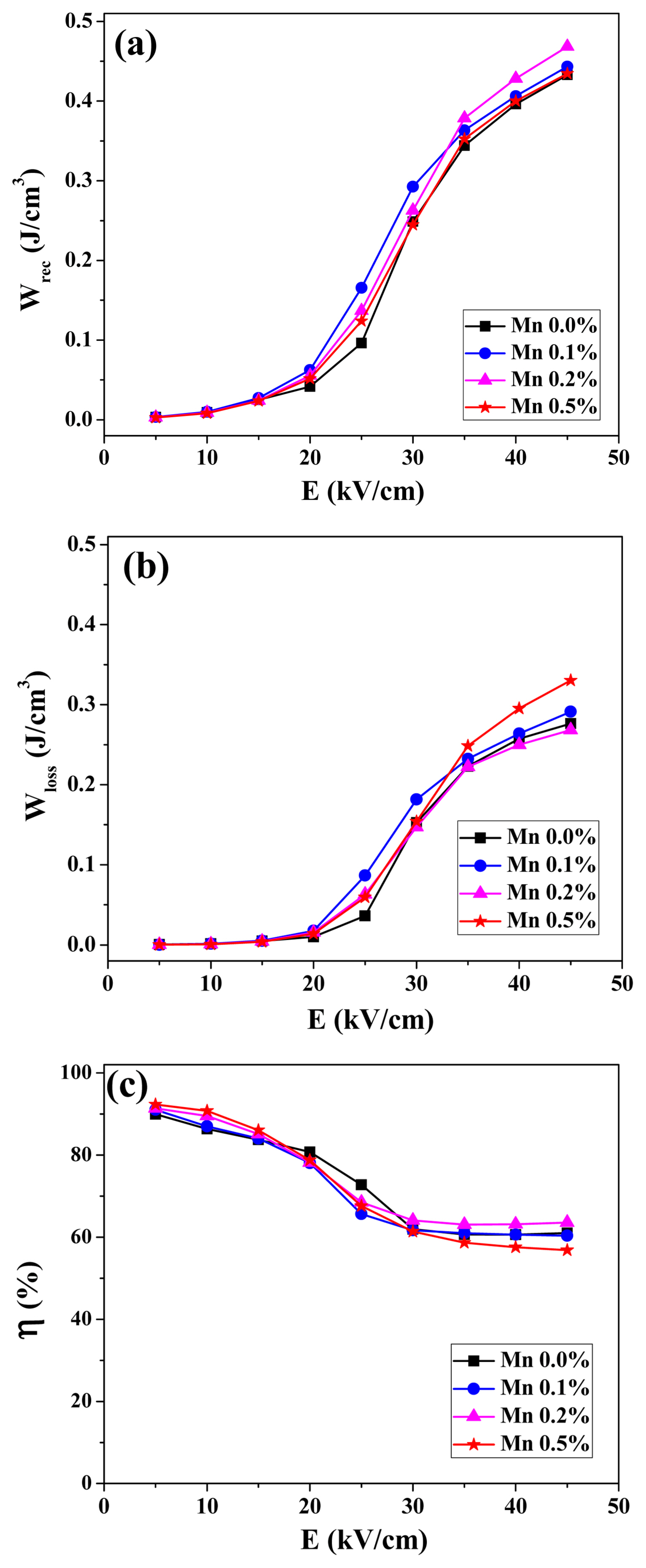

3.4. Energy storage properties

The P-E hysteresis loops are being used for calculation of the recoverable energy-storage density (Wrec), energy-loss density (Wloss), and efficiency (η). The P-E hysteresis loops (Fig. 4(a)-(d)) were used for the calculation of Wrec and η of a ceramic capacitor from the following equations:4,28,38)

where E is the applied electric field, P is the polarization, Pmax is the maximum polarization, Pr is the remnant polarization, and Wloss is the energy-loss density of the ceramics and can be calculated through a numerical integration of the closed area of the P-E hysteresis loops.

The changes in Wrec, Wloss, and η of Mn-doped PLZT 7/82/18 AFE ceramics as a function of the electric field is shown in Fig. 6(a)-(c). The energy storage and efficiency of the PLZT AFE ceramics with Mn = 0.2% doping were found to be ~ 0.46 J/cm3 and ~ 63%, respectively. Although the energy storage is not as high, a moderate efficiency within the range of 30 to 50 kV/cm was obtained with a negligible change in the electric field, thereby demonstrating the reliability of the ceramics. All energy density related parameters are given in Table 1.

3.5. Pyroelectric properties

Pyroelectricity is also an extremely important property of the electro-ceramics, in which the temperature fluctuations in an environment considered to be low-grade waste are converted into electrical energy. Assuming there is a pyroelectric material with a temperature gradient dT, the polarization change dP occurring in the materials and the pyroelectric coefficient p can then be defined as follows:39-41)

where σ and E are the constant stress and constant electric field, respectively, and Ps is the electrical polarization of the pyroelectric material.

When the pyroelectric capacitive structure is connected to the load, a corresponding electric current flows through the load as follows:39, 40)

where t, Q, T, and A are the time, induced charge, temperature, and surface area of the electrode, respectively.

The pyroelectric properties of the poled Mn-doped PLZT 7/82/18 AFE ceramics were also measured from room temperature to 225°C. The PLZT ceramic was heated, the pyroelectric current (Ip) was measured, and the pyroelectric coefficient (p) was calculated from equation (5) as a function of temperature (Fig. 7(a)-(b)). The pyroelectric current shows an increase with an increase in Mn-doping. The Mn = 0.5% doped PLZT AFE ceramics show the highest Ip and p of ~ 2,000 μC/m2K at 187°C. The value of the pyroelectric current depends upon the change in rate of the temperature and the electrode area of the ceramics.

4. Conclusions

PLZT 7/82/18 AFE ceramics, doped with manganese, were successfully synthesized using a pure perovskite phase, high density, and uniform grains without secondary phases. The dielectric constant was found to be high at ~ 2,128 with a low dielectric loss for 0.1% Mn-doped PLZT ceramics. The P-E loops show a typical AFE behavior for Mn-doped PLZT ceramics. The breakdown field decreases as the Mn-doping increases in PLZT ceramics. PLZT ceramics with 0.2% doped Mn shows the highest energy density and efficiency. The pyroelectric properties of Mn-doped PLZT ceramics were also found to be good with a pyroelectric coefficient of ~ 2,000 μC/m2K at 187°C.